- Water treatment

- Seawater Desalination

- Pure water /Ultra Pure Water

- Wastewater Treatment

- Sewage treatment

- Sewage/Wastewater Reuse

- Electrochlorination plant

- Carbonization Facility

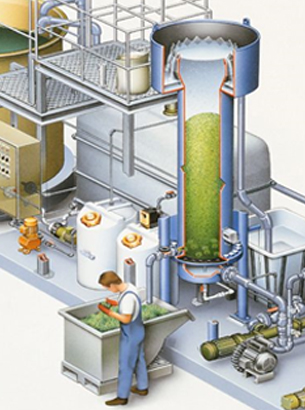

- Crystalactor

Crystalactor

Cheongam Water Treatment & Engineering Co., Ltd. is a specialized company that provides all solutions for water treatment processe

-

Amsterdam soft water facility

- For drinking water

- Number of reactors: 10

- Processing capacity: 8,500 m³/h

- The produced pellets are used for livestock feed

- Operating 50 plants worldwide

-

Perth Australia, Perth Australia

- Applied concrete structure for the first time

- Processing capacity : 120,000 m³/day

- Design and construction

- The basic and working design of the process is carried out by DHV

- Project was won by innovative design that resulted in lower construction costs and lower chemicals consumption

-

Dejtár Waterworks - Hungary

- Drinking water treatment

- 1 Reactor

- Processing capacity: 320 m³/h

- Into existing technology and building afterwards installed

-

Chen Chin Lake - Taiwan

- World's largest Crystalactor® installation site

- 처Processing capacity : 450,000 m³/day

- Softening of surface water

- Process & Basic Design plus detailed Reactor Design by DHV

- Composed of 8 concrete reactors (4.8x4.8 m)

- removable dosing rack NaOH

-

Fong Shan, Taiwan

- Client: TWSC & Tong Hsin Water Business

- 350,000 m³/day domestic water plus 450,000 m³/day industrial water supply

- 6 concrete Crystalactor’s

- Services (for whole flow scheme) :

- Design & commissioning

- Detailed design & construction supervision & supply & delivery of key equipment

- 15 years Operation & Maintenance

-

Recovery of phosphate

- Applicability

- Can be installed directly in the main process (end-of-pipe)

- Can be combined with anaerobic bio-treater

- In side stream with biological phosphate concentration

- Main product

- Ca3(PO4)2

- Mg3(PO4)2

- MgNH4PO4

- Zn3(PO4)2

- Applicability

-

Westerbork

- Removal of phosphate

- Urban sewage treatment plant

- Processing capacity : 12,000 p.e.

- The produced pellets are recycled in the phosphate processing industry

-

Geestmerambacht

- Phosphate removal facility in urban sewage treatment plant

- Processing capacity : 230,000 p.e.

- Installed at the rear end of biological phosphate concentration (anaerobic tank)

-

Potato starch, USA

- MgNH4PO4 - Crystallization

- To prevent piping/boiler scale

- Simultaneous removal of ammonia nitrogen

- The produced pellets are applied as fertilizer

-

Phosphate recovery USA

- Dairy processing plant, Wisconsin (USA)

- Installed at the rear end of the aerobic biotreater

- Single reactor (Ø 3.0 m)

- Processing capacity : 125 m³/h with 25 ppm P

- Use of lime

- Effluent concentration < 2 ppm P

- Built by US licensee, Procorp In

-

Chroomwerk

- Nickel recovery from plating plant

- 1,000 ppm Ni ⇒ < 1 ppm

- Pellets are reused in the process bath

-

AKZO Chemicals

- Multi-purpose

- Zn, Ni, Te-recovery

- Pellet reactor 800 mm

-

Shell Berre – Kraton Polymers

- Catalyst recovery in the polymer manufacturing process

- Recovery of both nickel and aluminum

- Process integrated

- Turn-key project

-

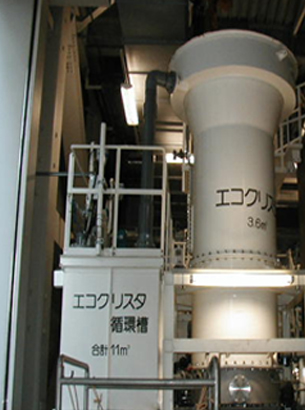

EcoCrysta - Japan

- EcoCrysta = Crystalactor

- Licensee Organo corporation

- Awarded as best environmental product by Japan Society of Industrial Machinery Manufactures (2002)

-

Du Pont

- Fluoride recovery from Printing Industry

- Pellet Reactor 1,000 mm

- 700 ppm F ⇒ < 10 ppm

- Start-up : 1990

-

Ricoh - Japan

- Process Basic Design by DHV

- Constructed by licensee Organo Corp.

- Pellet Reactor 1,000 mm

- 1,000 ppm F ⇒ < 15 ppm

- 100 ppm P ⇒ < 10 ppm

- In operation since : April 2001

- Pellets recycled to HF - supplier

- Awarded as best environmental technology!

-

MEMT - Taiwan

- General wastewater + pre-treated CMP from Semiconductor

- Process / Basic Design by DHV

- Constructed by DHV Hsiung Ling / Tai-En

- Pellet reactor 1,000 mm

- 500 - 4,000 ppm F ⇒ < 15 ppm

- In operation since : October 2001

-

mec - Belgium

- demonstration test F - concentrates

- Pellet Reactor 600 mm

- from grams F per liter ⇒ < 10 ppm

-

Ricoh - Japan

- Process/Basic Design by DHV/Organo

- Constructed by licensee Organo Corp

- Pellet Reactor 600 mm

- 500 ppm ⇒ 15 ppm

- In operation since: 2002

-

Zinc refinery

- wash water from gas scrubber

- Pellet Reactor 2,500 mm

- 800 ppm F ⇒ < 60 ppm

- water contains high Zn, SO4, As, Se

- integrated with As-removal and biological SO4-reduction

-

Shell Solar - Germany

- Waste water from solar cell production

- Pellet Reactor 600 mm

- From 900 ppm F ⇒ < 30 ppm F

- Turn-key

- In operation since: May 2003

-

Semiconductor - Japan

- EcoCrysta for micro-electronic productions

- Pellet Reactor 1,200 mm

- From 200-800 ppm F ⇒ >10 ppm F